Koolnar™

System Overview

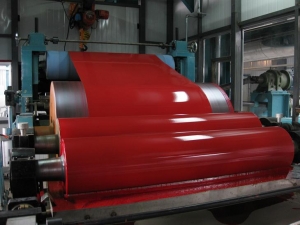

The Koolnar™ PVDF coil coating system manufactured and distributed globally by Continental Coatings Inc. and Yung Chi Paint and Varnish Manufacturing Company Ltd., is a Premium 70% PVDF coil coating system engineered for monumental building product applications and severe exterior environments that require long life and extended warranty coverage. The Koolnar™ system uses licensed Kynar®and Hylar®PVDF Fluoropolymer technology which is ultra resistant to U.V. radiation and natural weathering. Koolnar™ uses only the highest quality long lasting ceramic and metallic pigmentation to insure optimal exterior color fastness and longevity. This system is also available in multiple coats and various specialty high build systems. Koolnar™ may be applied over the Universal PU-11 High Molecular Weight Urethane Primer or PU-30 High-build Urethane primer systems for extreme environment and extra long service life warranted building product applications.

Application Parameters

The Koolnar™ system is designed for trouble free coil coating line application and has been run for well over 2 decades on new and old coil lines around the world. Standard topcoat DFT is .70-.80 mils, which allows for optimal application consistency, color stability and exterior performance. Koolnar™ was formulated to provide improved stain resistance and cleanability as well as scratch resistance and surface toughness. Superior primer corrosion resistance and substrate adhesion along with chemically enhanced topcoat intercoat adhesion greatly minimize field scratch and wet stack storage complaints, and handling, transporting, and storage related claims.

Commercial Uses

The Koolnar™ system can be formulated in standard, medium, as well as low gloss/low sheen finishes and supplied in limited colors. This premium coating supports an extended warranty and can be applied to a variety of adequately cleaned and treated metal substrates including: Hot Dipped Galvanized, ZnAl, Galfan®, ZAM®, Aluminum, and Stainless Steels. Koolnar™ is formulated with IR Reflective COOL ROOF ceramic pigment technology and can be designed to meet and exceed U.S. Energy Star®requirements. It is most ideal for high-end construction related products like composite panels, high U.V. exposure roofing, and acidic/alkaline corrosive environments like industrial manufacturing facilities and power plants.

| APPLICATION | ||

| SPECIFICATIONS | TEST | RESULT |

| Application Method | Reverse Roll Coat | |

| Substrate | Aluminum, HDG, Galvalume®, Galfan®, ZAM® | |

| Pretreatment | Standard clean and treat | Chrome or approved non-chrome |

| ASTM D 4138 | Dry Film Thickness | Top coat: 0.7 to 0.8 mils Primer: 0.2 to 0.3 mils Total system: 0.9 to 1.1 mils |

| ASTM D 4212 | Viscosity (No. 2 Zahn cup) | 25 to 45 seconds |

| ASTM D 1475 | Weight Per Gallon | 9.0 to 12.0 pounds per gallon |

| ASTM D 2697 | Solids Per Volume | 35 to 42% |

| ASTM D 2369 | Solids Per Weight | 45 to 65% |

| Reducing Thinner | Reducing Solvent | Isophorone / DBE |

| ASTM D 3960 | VOC (Theoretical) | 4.0 to 4.8 pounds per gallon |

| Clean-up Solvent | Aromatic/Ketone | |

| Peak Metal Temperature | 465 to 485 F | |

| TECHNICAL DATA | ||

| SPECIFICATIONS | TEST | RESULT |

| ASTM D 523 | Specular Gloss at 60 | 6 to 35 |

| ASTM D 3363 | Pencil Hardness | F to 2H |

| ASTM D 4145 | T-Bend | 1T to 4T with no loss of adhesion |

| ASTM D 3359 | Cross Hatch Adhesion | No loss of adhesion |

| ASTM D 2794 | Reverse Impact | Galvalume or HDG: 3x metal thickness inch-pounds, no loss of adhesion Aluminum: 1.5x metal thickness inch-pounds, no loss of adhesion |

| ASTM D 2247 | Humidity Resistance 1,000 hrs. Humidity Resistance 3,000 hrs. | Galvalume or HDG: Creep from scribe < 1/8 inch (3mm), no field blistering Aluminum: Creep from scribe < Creep from scribe < 1/8 inch (3mm), no field blistering |

| ASTM B 117 | Salt Spray Resistance 1,000 hrs. Salt Spray Resistance 3,000 hrs. | Galvalume or HDG: No Blistering Aluminum: No Blistering |

| ASTM D 2244 ASTM D 4214 | South Florida Exposure | Color: No more than 5 Hunter (E) units Chalk: Rating no less than 8 |

| ASTM D 870 | Water Immersion 100 F 500 hrs. | No Field blisters with minimal color change |

| ASTM D 1308 | Chemical Resistance (15 mins.) | No significant color change |

| ASTM E 84 | Flame Spread Classification | Class I or A |

| ASTM D 968 | Abrasion Resistance | Total Sand = 65 +/- 5 (Dft dependent) |

|

|

|

|

|

|

|

|